You’ll make smarter pool investment decisions when you understand five key fiberglass pool material properties. Flexible design adaptations prevent cracking during freeze-thaw cycles, while uniform shell thickness (3/16″ to 3/8″) delivers superior strength-to-weight ratios. Non-porous gelcoat surfaces resist algae adhesion, and vinyl ester resins withstand chlorine, saltwater, and UV exposure. Built-in high-density foam insulation cuts heating costs by up to 33%. Each property contributes specific performance advantages worth examining in detail.

Durability That Withstands Decades of Weather and Ground Movement

When you’re evaluating pool materials for long-term investment, fiberglass delivers measurable durability that concrete and vinyl alternatives can’t match. The shell’s flexible design adaptations allow it to flex slightly during ground shifts and freeze-thaw cycles without cracking, a critical advantage over rigid concrete structures.

Your fiberglass pool’s corrosion resistant construction combines multiple protective layers: a UV-stable gelcoat surface, vinyl ester resin for waterproofing, and reinforced fiberglass for structural strength. This non-porous composition resists algae penetration, chemical degradation, and environmental wear. The non-porous surface also means minimal maintenance requirements compared to concrete or vinyl options, reducing your long-term ownership costs. The protective gel coat specifically shields your pool from UV rays and chemicals, preventing premature deterioration of the underlying structure.

Data shows fiberglass pools installed in the 1980s remain operational today, with average lifespans reaching 25-30 years and high-quality models exceeding 40+ years. The gelcoat maintains its integrity for 20-30 years before refinishing becomes necessary. Proper care and maintenance can extend your pool’s functional lifespan well beyond these averages, with some owners enjoying their pools for four decades or more.

Superior Strength for Maximum Load-Bearing Performance

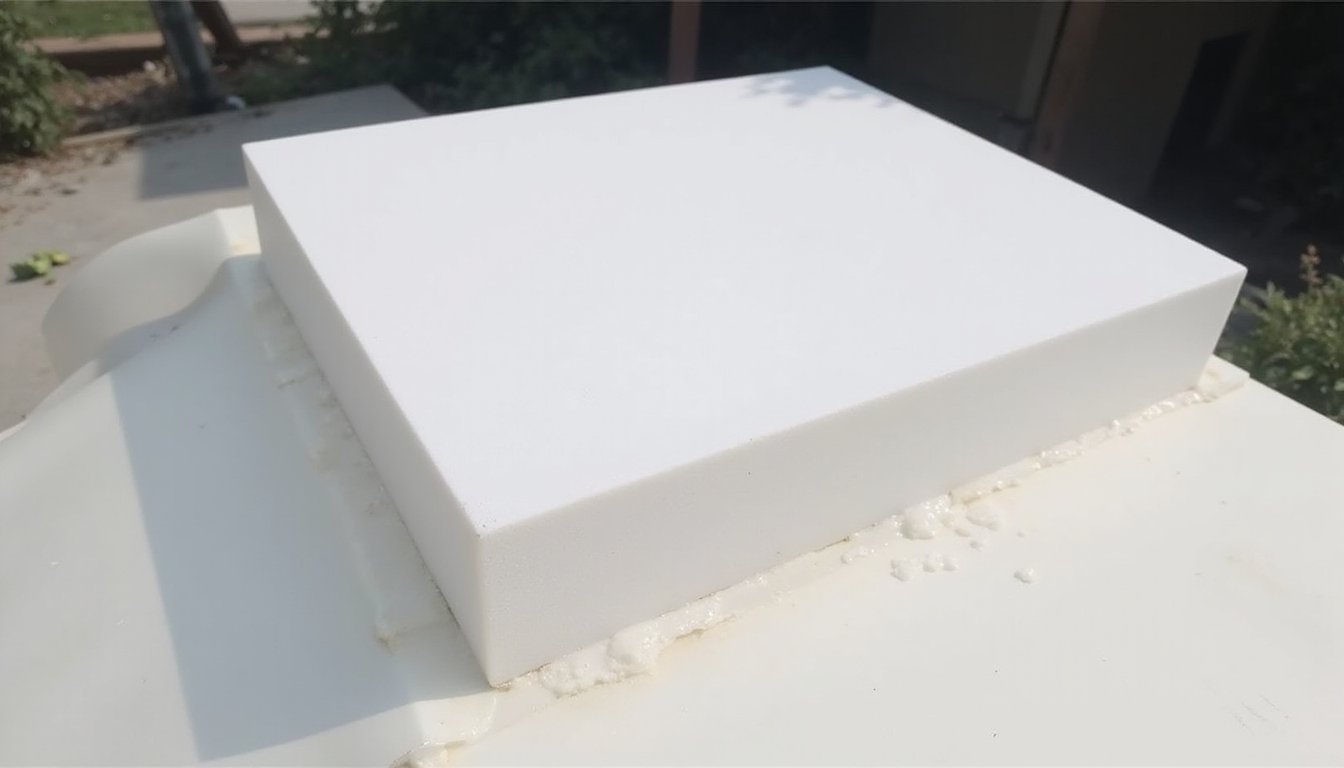

Although fiberglass pools weigh just 2,000, 3,500 lbs depending on size, their engineered shell construction delivers exceptional load-bearing performance through precise material specifications. You’ll find uniform thickness distribution ranging from 3/16″ to 3/8″ across the shell, eliminating weak points under pressure while maintaining ideal rigidity-to-flexibility ratios.

| Specification | Measurement | Function |

|---|---|---|

| Shell Thickness | 3/16″, 3/8″ | Load distribution |

| Reinforcement Mesh | 6mm / 10x10cm | Base strength |

| Bond Beam | 8″ concrete | Perimeter lock |

Your pool achieves enhanced perimeter strength through rebar integration with 8″ concrete bond beams. Cross-Lynx polymerization fuses composite layers, creating corrosion-resistant structural webs that outperform concrete under soil movement stress. The plastic material gains its impressive strength-to-weight ratio from glass fiber and resin reinforcement. These material properties contribute to durability and longevity superior to vinyl liner or concrete pools. The non-porous gelcoat finish provides a smooth surface that resists algae growth, reducing chemical accumulation and simplifying ongoing maintenance.

Smooth Non-Porous Surfaces That Resist Algae and Debris

Because fiberglass pools feature proprietary AQUAGUARD®X gelcoat technology, their surfaces achieve an ultra-smooth, non-porous finish that fundamentally changes maintenance requirements. This shiny coating prevents algae adhesion, reducing chemical needs by up to 70% compared to concrete alternatives.

AQUAGUARD®X gelcoat technology creates a non-porous surface that cuts chemical maintenance by up to 70% compared to concrete pools.

The non-porous surface delivers measurable benefits:

- Algae resistance: Smooth walls inhibit biological growth that plagues porous materials

- Debris repulsion: Dirt can’t embed, minimizing scrubbing frequency

- Swimmer comfort: Non-abrasive texture prevents scrapes, bruises, and blisters

- Reduced maintenance: No acid washing or resurfacing required

- Chemical efficiency: Salt chlorinators operate in an ideal manner without delamination risks

You’ll experience a safer swimming experience with slip-resistant textures on walking areas while enjoying gentler water chemistry. The gelcoat maintains its luxurious texture indefinitely, eliminating the degradation cycles common with concrete pools. This exceptional durability makes fiberglass the superior investment for homeowners seeking long-term value without frequent intervention. Many manufacturers back their fiberglass pool shells with warranties up to 25 years, reflecting the material’s proven resilience and long-term performance. The fiberglass material’s inherent flexibility allows the pool shell to adapt to ground shifts without cracking, providing reliable structural integrity across various soil conditions.

Chemical Resistance That Saves Money and Protects Water Quality

Fiberglass pools derive their exceptional chemical resistance from the synergistic combination of vinyl ester resins and specialized gel coat layers. These materials withstand chlorine, saltwater, and UV exposure without degradation, maintaining structural integrity for decades.

| Property | Performance Specification |

|---|---|

| Temperature Range | -40°C to +80°C |

| Ideal LSI Range | -0.3 to +0.3 |

| Service Life | 10+ years in chlorinated applications |

| pH Impact | Neutral (non-reactive) |

You’ll benefit from inert surface properties that don’t affect water chemistry, requiring less acid addition for pH balance. The gel coat’s corrosion prevention strategies eliminate rust and salt damage concerns. This chemical stability translates directly to reduced maintenance costs, you won’t face frequent repairs or premature material replacement that plagues reactive pool surfaces. The smooth, non-porous surface of fiberglass also resists algae growth, further reducing the need for excessive chemical treatments and cleaning efforts. Unlike other pool types, fiberglass requires no resurfacing or liner replacements, providing significant long-term savings over the life of your pool. As a cost-effective alternative to stainless steel, fiberglass profiles offer the same corrosion resistance while reducing overall weight and installation expenses.

Energy-Efficient Insulation That Reduces Heating Costs Year-Round

When you’re evaluating pool materials for thermal efficiency, the insulation properties directly impact your long-term operating costs. Fiberglass delivers enhanced insulative properties through its built-in high-density foam layer, minimizing heat transfer to ground and air. This design enables consistent temperature maintenance while reducing energy demands by 30% compared to alternative materials. The superior heat retention properties of fiberglass result in lower energy consumption for heating, delivering more consistent swimming temperatures throughout the season.

Key Performance Metrics:

- Monthly heating costs drop 33% when switching from concrete to fiberglass

- Cold climate installations achieve 20-30% heating cost reductions

- 10-year electricity costs for heating and pumping total approximately $8,400

- Daily pump operation requires only 4-6 hours versus extended runtimes for vinyl

- Reduced evaporation rates preserve heat and lower utility expenses

The Thompson family documented their bills decreasing from $180 to $120 monthly, a $720 annual savings that compounds over your pool’s lifetime. These savings become even more significant when you consider that fiberglass pools already require 75% fewer chemicals than concrete alternatives, further reducing your overall maintenance expenses. Many pool owners find that fiberglass is an excellent insulator that helps extend the swimming season well beyond what other pool types allow.

Frequently Asked Questions

How Does Fiberglass Pool Installation Time Compare to Concrete Pool Construction?

You’ll complete a fiberglass pool installation timeline in 3 to 5 weeks, while concrete construction demands 3 to 6 months. Fiberglass shells install in 2 to 3 days post-delivery, drastically reducing labor requirements compared to concrete’s 28 to 30 day curing period alone. Your fiberglass project allows concurrent site preparation during manufacturing, whereas concrete’s multi-stage process, excavation, rebar placement, spraying, and finishing, creates extended on-site labor requirements and increased weather delay susceptibility.

Can Fiberglass Pools Be Customized in Different Shapes and Sizes?

Yes, you can customize fiberglass pools through extensive custom design options. Pool shape versatility includes freeform, kidney, rectangular, Roman (23-28 feet), and Eclipse models (30-40 feet). You’ll select from sizes up to 16 feet by 40 feet maximum due to transportation regulations. Built-in features like tanning ledges, integrated spas, and splash pads enhance functionality. Surface customizations include gelcoat colors ranging from Maya Blue to Granite Grey, waterline tiles, and 7-mode LED lighting systems.

What Is the Average Lifespan of a Fiberglass Pool Gelcoat Finish?

Your fiberglass pool gelcoat finish typically lasts 10-15 years with proper care, though well-maintained surfaces can exceed 25-30 years. Gelcoat maintenance requirements include maintaining pH levels at 7.2-7.6, total alkalinity between 80-120 ppm, and calcium hardness at 200-400 ppm. When you notice fading, chalking, or small cracks, you’ll want to explore gelcoat resurfacing options to restore your pool’s protective barrier and extend its functional lifespan.

Are Fiberglass Pools Suitable for Saltwater Conversion Systems?

Yes, fiberglass pools are highly suitable for saltwater conversion systems. Your pool’s non-porous gel coat surface delivers exceptional corrosion resistance, unlike concrete or vinyl alternatives with vulnerable metal components. The impermeable fiberglass material demonstrates superior chemical compatibility with salt-generated chlorine at typical levels of 2,500-4,000 ppm. You’ll need to maintain 99%+ purity pool salt and clean your chlorinator cell seasonally to guarantee optimal system performance and durability.

How Do Fiberglass Pool Costs Compare to Vinyl Liner Pools Long-Term?

You’ll find fiberglass pools cost less long-term despite higher upfront prices ($55,000-$100,000 versus $40,000-$70,000 for vinyl). Your 10-year maintenance requirements total approximately $4,000 for fiberglass compared to $7,000 for vinyl. Repair feasibility favors fiberglass since it lasts up to 30 years without liner replacement, while vinyl demands $6,000 replacements every 5-9 years. Over a decade, vinyl totals $58,000-$94,000 versus fiberglass at $63,000-$112,000, but fiberglass typically proves more economical long-term.