When evaluating fiberglass pool construction, you’ll want to identify several key materials. Premium shells feature vinyl ester resin as the waterproofing barrier, while polyester resin provides structural bulk. Marine-grade fiberglass forms the backbone, and advanced reinforcement fibers like Kevlar and basalt add impact resistance at stress points. The gelcoat surface layer delivers UV protection and chemical resistance. Understanding how these materials work together reveals what separates quality construction from standard offerings.

Understanding the Core Components of Fiberglass Pool Shells

When you examine a fiberglass pool shell, you’re looking at a precisely engineered composite structure built from multiple specialized layers. The gelcoat layer forms your first defense, protecting against UV rays and chemicals while delivering a smooth, cleanable finish. Manufacturers apply this coating first onto molds, where it cures under controlled conditions for ideal adhesion. This gelcoat surface also provides natural algae resistance, reducing the need for chemical treatments and scrubbing throughout the pool’s lifetime.

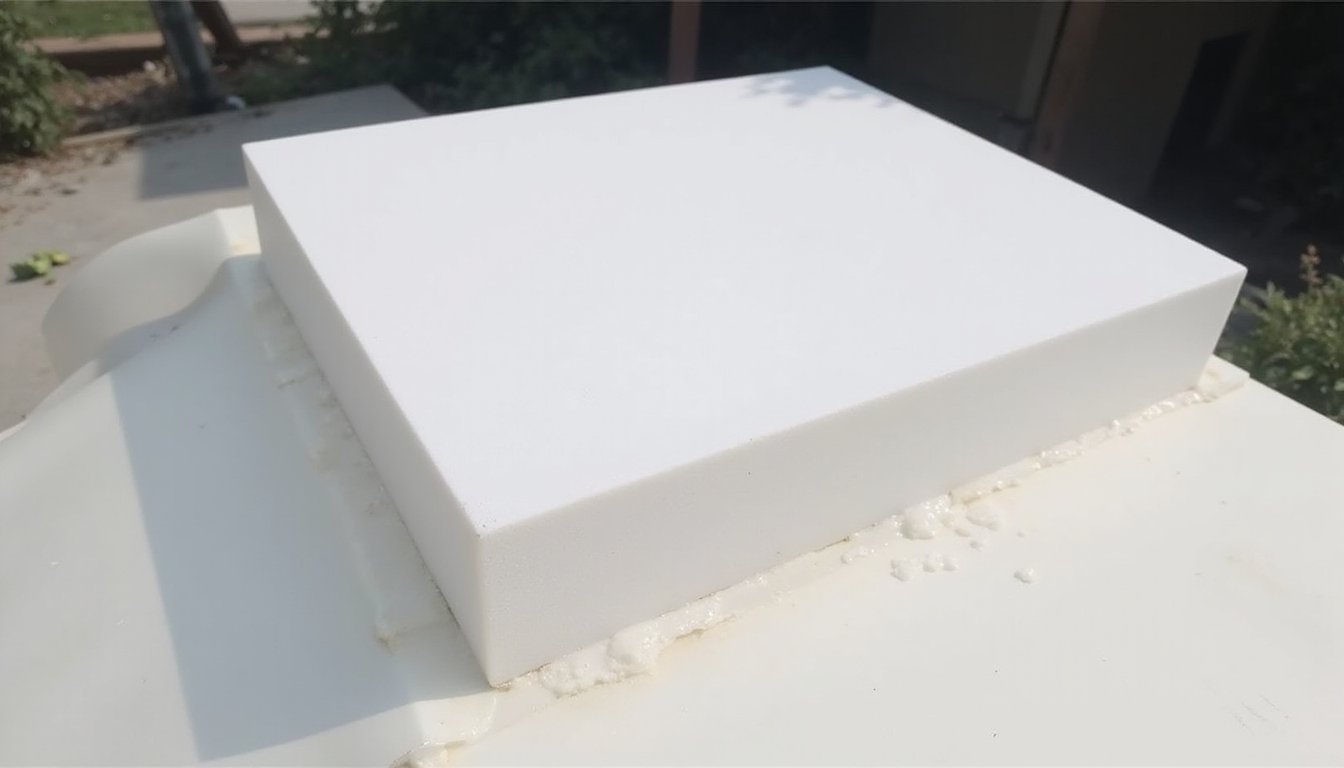

Beneath the gelcoat, you’ll find six chopped fiberglass layers creating approximately ⅜-inch thickness. Raw material innovations have transformed this construction, the initial layer uses vinyl ester resin for waterproofing, while subsequent layers incorporate polyester resin. Technicians roll each layer to eliminate air bubbles. Woven roving reinforcement targets stress points, preventing cracks under pressure. Today’s sustainable manufacturing methods integrate these components efficiently, maximizing structural integrity while minimizing waste. The marine-grade fiberglass provides the structural backbone, offering flexibility and strength to withstand ground movement and environmental stresses throughout the pool’s lifespan. Reputable manufacturers construct pool shells with 5/8 inch to 1 inch thickness, which contributes to increased strength and enhanced longevity compared to thinner alternatives.

Vinyl Ester Resin: The Premium Waterproofing Layer

Although polyester resin dominates standard fiberglass construction, vinyl ester resin stands as the gold standard for premium pool shells requiring superior waterproofing and structural performance. The resin formulation incorporates epoxy vinyl ester compounds that deliver enhanced chemical resistance and flexibility compared to standard alternatives.

You’ll find vinyl ester creates an impermeable barrier that eliminates water absorption, swelling, and blistering, critical application considerations for preventing osmosis damage. This material bonds more effectively to fiberglass layers, producing 111% stronger construction than standard pools per independent testing.

The enhanced molecular structure absorbs stress from temperature fluctuations and ground movement without cracking. This flexibility prevents the stress cracks and fractures that commonly affect pools built with less resilient materials. You can expect 20+ years of service life with minimal maintenance requirements. Premium manufacturers specify full vinyl ester construction backed by lifetime structural osmosis warranties. While vinyl ester costs more upfront, it saves money in the long run by eliminating the frequent repairs that polyester resin pools typically require. Standard manufacturers typically use only one layer of vinyl ester resin, leaving remaining layers vulnerable to degradation over time.

Polyester Resin and Its Role in Structural Bulk

Beyond the vinyl ester barrier coat, you’ll find polyester resin forming the structural bulk of your fiberglass pool shell through multiple laminated layers. This cost-effective material bonds with chopped strand roving and woven fiberglass to build the primary thickness that gives your pool its mechanical strength. The resin’s water-resistant bond makes it particularly well-suited for wet environments like pools and spas. While polyester resin costs roughly half as much as vinyl ester, it delivers the essential structural mass needed when properly layered with reinforcing fibers. The resulting pool shell features a smooth gelcoat surface that is non-porous and easy to clean, contributing to the low maintenance reputation of fiberglass pools. However, premium manufacturers like Leisure Pools use vinyl ester resin throughout their entire manufacturing process rather than just as a barrier coat, accounting for 70% of the pool shell makeup for superior performance.

Building Structural Layers

Once manufacturers apply the vinyl ester barrier layer, they shift to building the pool shell’s structural bulk using polyester resin combined with chopped strand fiberglass. You’ll find this material sprayed via chopper gun, then rolled to achieve proper layer thickness and guarantee bubble elimination throughout the laminate.

The construction process involves multiple polyester layers strategically reinforced with woven roving at high-stress points. This combination delivers the flexural and tensile strength your pool requires for long-term durability. Each application must be rolled thoroughly to saturate fiberglass strands and remove trapped air that could compromise structural integrity. This multi-layered construction approach, with structural fiberglass reinforced with resins, creates the robust and durable structure that composite pools are known for.

A final sprayed polyester layer completes the shell formation before curing. While polyester resin costs less than vinyl ester, it provides essential rigidity when properly combined with fiberglass reinforcement in this critical bulk-building phase.

Cost-Effective Bulk Material

Because polyester resin costs noticeably less than vinyl ester alternatives, it serves as the primary bulk-building material in fiberglass pool shell construction. You’ll find manufacturers apply this resin with chopped fiberglass strand roving to build shell thickness to approximately ⅜ inches. This approach delivers cost effective alternatives while maintaining structural integrity through millions of interwoven glass threads.

However, you should understand the long term durability concerns associated with polyester’s semipermeable nature:

- Water permeation risk: Unprotected polyester allows moisture infiltration, potentially causing osmotic blisters

- Barrier dependency: Requires vinyl ester first layer to prevent gelcoat degradation

- Warranty considerations: Gelcoat coverage protects against blister-related failures

Despite these limitations, polyester resin reinforces sidewalls and stress points effectively when properly layered behind waterproof barriers, enabling budget-friendly production without sacrificing core structural performance.

Marine-Grade Fiberglass as the Structural Backbone

While gelcoat provides the visible surface and chemical resistance, marine-grade fiberglass forms the structural backbone that gives your pool shell its exceptional flexibility and strength. This advanced composite resists cracking from ground movement and adapts to changing soil conditions without compromising material integrity.

During manufacturing, workers apply chopped fiberglass with vinyl ester resin immediately after the gelcoat spray, creating a watertight barrier. They add woven roving at stress points for reinforcement, then layer polyester resin in subsequent structural applications. Structural comb materials are positioned under steps and benches to form supportive ribs that prevent side wall bulging.

You can verify marine-grade fiberglass through construction specifications listing woven roving and marine-grade labels. The shell accommodates environmental factors like temperature fluctuations and extreme climates without fading or blistering. This engineering delivers superior impact resistance over concrete alternatives, preventing stress cracks while maintaining shell weight within 5% of design specifications. The construction process incorporates a Centurion Core that further reinforces durability and resistance to corrosion. With pools manufactured in Orlando, FL, Rainforest Pools ensures each shell meets rigorous American-made craftsmanship standards before installation.

Advanced Reinforcement Fibers: Kevlar, Carbon, and Basalt

When you’re evaluating advanced reinforcement fibers for your fiberglass pool shell, Kevlar’s exceptional impact absorption protects high-stress bottom areas from micro-cracking under everyday wear and environmental loads. Basalt fiber offers you a lightweight yet robust alternative, delivering tensile strength comparable to carbon fiber while providing superior flexibility and chemical resistance against pool treatments. Both materials integrate seamlessly into vinyl ester resin matrices, enhancing your pool’s structural performance by 20-50% over standard fiberglass while maintaining a streamlined shell thickness. These advanced fiber composites contribute to pools that achieve a typical lifespan of 25-30 years or more when properly maintained. The resulting pool shells are less prone to cracking and chipping compared to concrete alternatives, making them an excellent long-term investment for homeowners. Leading manufacturers back these advanced composite constructions with lifetime structural warranties, giving you confidence in your pool’s long-term durability.

Kevlar Impact Resistance Benefits

Among the advanced reinforcement fibers used in premium fiberglass pool construction, DuPont™ Kevlar® stands out for its exceptional impact resistance and fatigue performance. You’ll find this aramid fiber delivers superior bend strength without stretching or shrinking, ensuring structural integrity enhancements that last decades. When embedded in vinyl ester resin, Kevlar’s impact resistance capabilities protect against external ground pressures and earth movement up to two feet.

Key Performance Specifications:

- Outperforms carbon fiber in bend strength and basalt fiber in fatigue resistance

- Withstands freezing-thawing cycles without flexural failure or cracking

- Maintains watertight performance under extreme environmental conditions

You’ll benefit from reduced long-term maintenance costs since Kevlar-reinforced pools resist the warping and deterioration common in other pool types. This technology supports lifetime structural warranties under demanding conditions.

Basalt Fiber Flexibility Advantages

Because basalt fiber combines exceptional tensile strength with superior bendability, it’s rapidly becoming the preferred reinforcement material for curved pool structures. You’ll find basalt rebar delivers twice the strength of steel while maintaining one-third the density, allowing thinner profiles that bend without breaking.

Concrete expansion compatibility makes basalt ideal for pool applications, it matches concrete’s thermal coefficient, eliminating stress fractures in curved walls. Standard coils of 328 feet conform easily to complex pool geometries, reducing overlaps and connection points.

The cost effective installation process stems from basalt’s non-conductivity, which eliminates grounding requirements, and its smooth edges prevent worker injuries common with rusty steel. You’re also reducing concrete volume since basalt’s higher strength-per-diameter ratio requires smaller reinforcement sections. Additionally, basalt resists pool chemicals, acids, and freeze-thaw cycling.

The Gelcoat Surface Layer and Its Protective Properties

The gelcoat layer serves as your fiberglass pool’s primary defense system, forming the outermost surface that you’ll see and touch throughout the pool’s lifespan. This non-porous barrier gets sprayed directly onto the mold before fiberglass lamination, creating a smooth, glossy finish with superior chemical resistance properties.

Gelcoat forms your pool’s invisible shield, a factory-applied barrier that protects while delivering that signature smooth, glossy finish.

You’ll notice the textured surface feel on steps remains anti-slip while staying gentle against skin, unlike abrasive concrete plaster. The gelcoat’s technical specifications deliver measurable advantages:

- UV-stabilized resins prevent fading and sun degradation over 25+ years

- Vinyl ester composition provides lifetime osmosis protection

- Non-porous structure reduces chemical requirements by up to 50%

This protective layer resists scratches, stains, and moisture penetration. You won’t need frequent resurfacing, and algae can’t attach to the sealed surface.

Woven Roving and Honeycomb Fiberglass at Stress Points

While the gelcoat provides surface protection, the structural integrity of your fiberglass pool depends on reinforcement materials strategically placed at high-stress zones.

Woven roving consists of continuous glass filaments woven into mesh patterns, providing flexibility where side walls meet the pool floor. This material prevents excessive flex that could crack your gelcoat while maintaining necessary rigidity. The layered application sequence alternates woven roving with chopped strand mat, reducing voids and ensuring proper resin saturation.

Honeycomb fiberglass forms structural ribs that prevent wall bulging from opposing water and earth pressures. You’ll find this material underneath steps, benches, and along bottom edges where over-flexing poses risks. These optimized layer configurations work together within Cross-Lynx Composite Technology, creating a pool shell that balances bending capability with shape retention during ground movement and installation stresses.

Factory Manufacturing Process and Quality Control Standards

Before fiberglass layers reach the mold surface, manufacturers establish precision through advanced CAD software that defines exact pool dimensions, contours, and feature placements. You’ll find that mold manufacturing tolerances remain within 1/8 inch, guaranteeing consistent shell accuracy across production runs. Steel reinforcement within molds withstands repeated heat cycles and plant movement.

Precision starts before the first layer, CAD software and tight tolerances ensure every fiberglass pool meets exact specifications.

The multi step gelcoat application creates your pool’s waterproof barrier. Technicians apply premium gel coat at specific thicknesses, monitored by TFM technology for uniformity.

- Mold preparation: Clean, waxed surfaces receive steel-reinforced frames maintaining dimensional accuracy

- Curing control: Temperature and humidity regulation ensures proper resin hardening over hours to days

- Final inspection: Quality teams verify structural integrity, gel coat smoothness, and defect-free shell completion

Key Quality Indicators That Signal Premium Fiberglass Construction

Quality control during manufacturing establishes baseline standards, but you’ll need to evaluate specific material specifications to distinguish premium fiberglass construction from standard offerings.

Examine the resin type first, vinyl ester resin creates a waterproof barrier with superior chemical resistance, unlike standard polyester alternatives. Marine-grade fiberglass incorporating DuPont™ Kevlar®, basalt, and carbon fibers delivers enhanced impact resistance and flexibility against ground movement.

Assess gel coat thickness carefully. Thicker applications provide UV resistance, prevent staining, and support thermal insulation performance throughout seasonal changes. The AquaGuard®X color system resists degradation from chlorine, salt water, and temperature cycling.

Verify warranty coverage reflects manufacturer confidence: lifetime structural and osmosis warranties, plus 10-year color guarantees. Premium shells also accommodate proper filtration system integration without compromising structural integrity.

Frequently Asked Questions

How Long Does a Fiberglass Pool Shell Typically Last Before Needing Replacement?

You can expect your fiberglass pool shell to last 25-50 years before needing replacement, with many reaching 60+ years under ideal conditions. Key pool shell longevity factors include manufacturing quality, gelcoat thickness, and corrosion-resistant resin systems. Your fiberglass pool lifespan considerations should focus on proper chemical balance, avoiding harsh non-fiberglass cleaners, and maintaining structural integrity through professional drainage protocols. High-quality shells often outlast the home itself, requiring only gelcoat refinishing every 15-30 years.

Can Fiberglass Pools Be Repaired if the Gelcoat Becomes Damaged?

Yes, you can repair damaged gelcoat on your fiberglass pool. Gelcoat repair techniques involve inspecting the damage, cleaning the area, sanding for adhesion, and applying fiberglass patches with resin for cracks or chips. Gelcoat refinishing options include matching gelcoat paste or spray formulated for chemical and UV resistance. You’ll need to cure for 24-48 hours, then wet sand progressively through finer grits up to 1500 before polishing to restore the original sheen.

What Colors Are Available for Fiberglass Pool Gelcoat Finishes?

You’ll find fiberglass pool gelcoat finishes in four main categories: standard colors (whites, light blues, sandy tones, grays), shimmer and sparkle options featuring metallic finishes with silver flake integration, dark dramatic hues (royal blues, volcanic black, graphite), and neutral earthy tones. Many manufacturers offer mottled finishes that incorporate multi-colored speckles for dimensional depth. Each finish specification affects light reflection properties, debris visibility, and heat absorption characteristics within your pool’s structural surface.

How Do Fiberglass Pool Costs Compare to Concrete or Vinyl Liner Pools?

You’ll find fiberglass pools offer superior lifetime value compared to concrete or vinyl liner alternatives. While vinyl presents the lowest upfront cost, you’ll face liner replacements every 7-15 years. Concrete demands higher installation expenses due to extended construction timelines. Fiberglass delivers 50% lower maintenance costs through its non-porous gel coat structure, reducing chemical requirements substantially. You’ll also benefit from enhanced energy efficiency through the shell’s natural insulation properties.

Are Fiberglass Pools Suitable for Cold Climates With Ground Freeze Cycles?

Yes, fiberglass pools excel in cold climates with ground freeze cycles. Their flexible composite construction absorbs soil expansion and contraction without cracking, unlike rigid concrete. You’ll benefit from inherent insulation requirements being lower due to the material’s thermal retention properties. For freeze protection methods, guarantee proper winterization of plumbing lines and install your shell within 3/4-inch crushed stone backfill to facilitate drainage and minimize frost heave pressure on structural components.